Price: $409.00

(as of Jun 14, 2024 17:16:57 UTC – Details)

Product Description

Ceramic 3D printers inspire a new generation of artists, sculptors and architects. With shapes that are impossible to achieve using traditional ceramic techniques, or which are too labor-intensive, MOORE1 clay 3d printer gives designers new ways to make ceramics.

Tradition meets the future

Ceramic &Clay 3D Printing-Closer to Ceramic Art.

MOORE1 ceramic 3D printer makes it possible to make ceramic products with complex processes, and moore1 has the advantages of simple operation, fast speed and high precision, which injects new vitality into ceramics.

Materials used for ceramic printing

Pottery Clay and Porcelain Clay PRINTING MATERIAL

MOORE1 can print a variety of materials such as pottery clay and porcelain clay, which is much more safety than traditional plastic FDM printing materials.

Mini Portable 3D Printer for Ceramic Enthusiasts

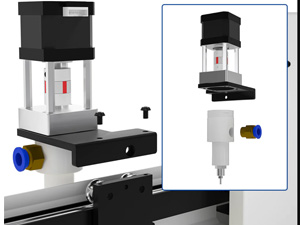

Screw Feeding Device

Screw Feeding Device

Newly designed screw feeding device and Super silent

OUT-OF-THE-BOX

OUT-OF-THE-BOX

MOORE1 is ready to use out-of-the-box, the whole machine arrives fully assembled. That means you don’t have to waste time reading manuals and putting parts together.

Detachable print head

Detachable print head

detachable print head

quick to clean and easy to maintain

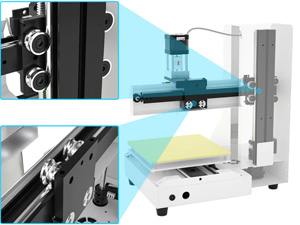

Stable axial operation

Stable axial operation

XYZ axis uses an external dual-axis roller guide

Stable and smooth operation

Smart user interface

Smart user interface

The 3.5inch full color touch screen interface is intuitive and easy to use for beginners.

Power to continue playing

Power to continue playing

Stop task or unexpected power failure during printing rebootable to continue printing

Line Width 0.5mm

Line Width 0.5mm

The range of line width is 0.3~3mm

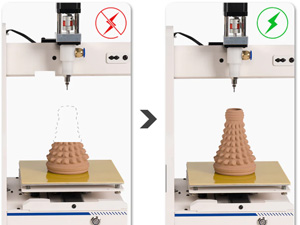

No Need Air Compressor

No Need Air Compressor

0.5l large capacity replaceable,adjustable synchronous feeding system

Application of Ceramic 3D Printing

practical training space

practical training space

Practical training space in vocational colleges and universities

innovation education

innovation education

Innovation education for makers in primary and secondary schools

channel cooperation

channel cooperation

Channel cooperation and social experience

new products developed

new products developed

New products developed by enterprises and research institutes

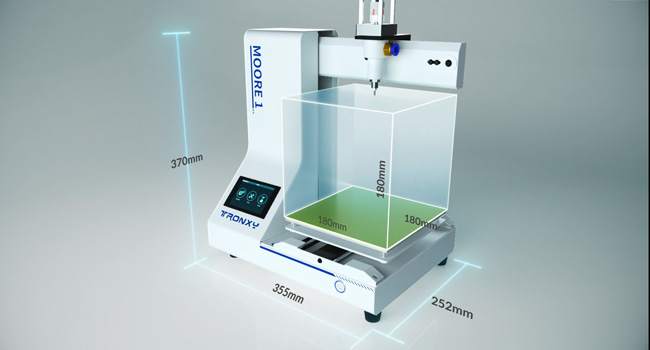

MOORE 1 Clay 3D Printer Parameter

Brand Tronxy Building Size 180*180*180mm Nozzle Size 1.0~3.0mm,2.0mm(Standard) Feeding Mode Electric push rod+screw extrusion Molding Technology Liquid deposition modeling LDM Layer Thickness 0.3-3.0mm,0.5mm(Standard) Materials Clay,ceramics,red porcelain and various liquid flowing materials Printing Speed 10-40mm/s,30mm/s is perferred Printing Mode U disk,TF card,USB data cable LCD Screen 3.5inch TFT touch screen Support File Format STL,G-Code,Obj Support Software Crua,slic3r,simplify3d,etc Machine Dimensions 355*252*370mm Machine Weight ≈7.5KG Environmental Requirements 8-40℃,humidity 20-80% Suppotr Operating System Windows

Liquid deposition molding ceramic 3d printer and Mini clay 3d rinter

ALL-IN-ONE MACHINE STRUCTURE:The whole machine arrives fully assembled. Once arrive, ready to use.

NEWLY DESIGNED SCREW FEEDING DEVICE:Replaceable, adjustable synchronous feeding system

NO NEED AIR COMPRESSOR:We developed electric putter instead of compressed air to guarantee outstanding printing quality and stability for prints. More easy to use for beginner.

FASTER PRINTING SPEED:TRONXY MOORE 1 clay 3d printer can print faster than the previous 3d printer series with a maximum print speed of 40mm/s.

#TRONXY #Ceramic #Printer #Liquid #Deposition #Molding #Mini #Clay #Printers #Ceramics #Hobby #Beginners #Kids #Adults #LCD #Screen #Building #Size7 #7inch180x180x180mm

![Mr.Shield [3-Pack] Designed For OnePlus (Nord N100) [Tempered Glass] Screen Protector [Japan Glass With 9H Hardness] with Lifetime Replacement](https://masmaz.com/wp-content/uploads/2024/11/61EAZqV2rsL._AC_SL1100_-150x150.jpg)